CN

CN

Introduction

Molybdenum Disulphide is added to lubricating oil, grease, as well as polytetrafluoroethylene, nylon, paraffin and stearic acid. Molybdenum Disulphide can improve lubrication and reduce friction. Molybdenum Disulphide can prolong lubrication cycle, reduce costs and improve working conditions. Molybdenum Disulphide can also be used as a release agent and forging lubricant for non-ferrous metals.

Molybdenum Disulphide is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulphide can be lubricated for a long time in the air below 350 ℃.

With more than ten years of research and development/ R&D experience, it can provide an annual output of 1,000 tons of Molybdenum Disulphide as a patented technology product.

Molybdenum Disulphide is a lubricant grade of molybdenum disulfide (MoS2) available in three grades-Technical, Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

SPECIFICATIONS

Packaging of Molybdenum Disulphide :

|

Package |

Package Size |

GW/NW |

Drums per pallet |

|

Fiber Drum |

36 cm * 48 cm |

27.4kg / 25kg |

18 |

|

Iron Drum (lined) |

40 cm * 70cm |

57.6kg / 50 kg |

8 |

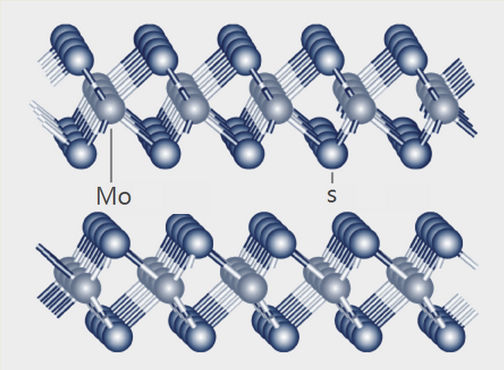

Figure 1: The relationship between crystal form and lubricating properties of Molybdenum Disulphide

There are only two crystal forms of Molybdenum Disulphide in nature: 2H (hexagonal) and 3R (trigonal). The formation law of 2H and 3R Molybdenum Disulphide is related to its formation temperature. 80% of molybdenite in nature is 2H type, only 3% is 3R type, and the remaining 17% is 2H and 3R mixed type. The scientific community believes that the 2H type has better lubricating effect than the 3R type.

Figure 2: Applications of Molybdenum Disulphide

Molybdenum Disulphide are widely used in Lubricant , Plastic modification , Grease , Brush , Valve guide and Brake pads.

Figure 3: microwave dryer

High heat utilization efficiency, molybdenum concentrate and water absorb microwaves evenly, and heat from the inside to the outside at the same time, making the moisture in molybdenum concentrate dry quickly. Factory panorama of Molybdenum Disulphide -annual output of 1000 tons

Figure 4: Packaging of Molybdenum Disulphide

Molybdenum Disulphide

2024-03-19 11:02:41

Molybdenum Disulphide is added to lubricating oil, grease, as well as polytetrafluoroethylene, nylon, paraffin and stearic acid Molybdenum Disulphide can improve lubrication and reduce friction Molybdenum Disulphide can prolong lubrication cycle, reduce...

share